Industry 4.0: The Future of Automation Is Here

Explore the impact of Industry 4.0 with this comprehensive guide! Learn about automation and its far-reaching implications for our world.

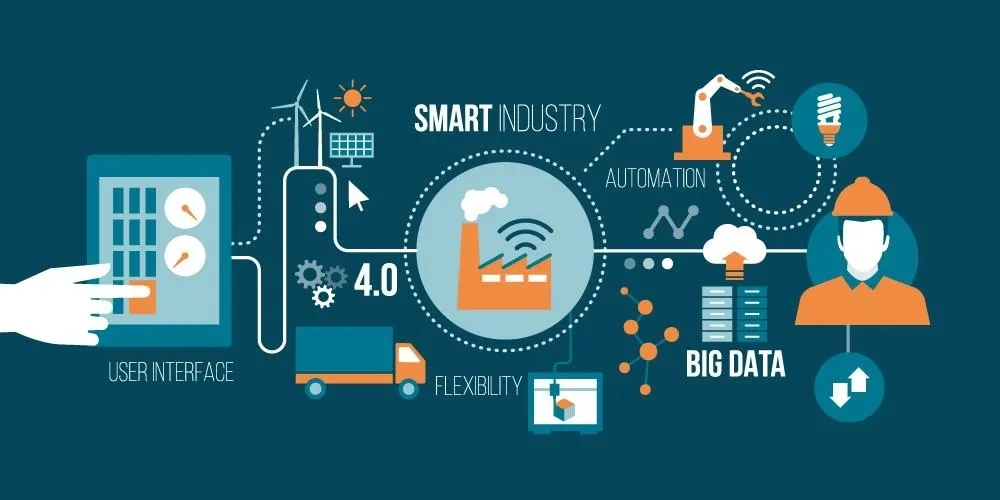

Industry 4.0 is the fourth industrial revolution, which refers to the digitization and automation of manufacturing. It is characterized by interconnectivity, automation, machine learning, and real-time data. Industry 4.0 marries physical production and operations with smart digital technology. The first three industrial revolutions came about as a result of mechanization, electricity, and IT.

Introducing the Internet of Things (IoT) into manufacturing is ushering in a fourth industrial revolution. Industry 4.0 creates new design principles along which the industry can organize itself. These include increased interoperability between manufacturing systems; improved flexibility in responding to customer needs; a modular design that allows for rapid reconfiguration of production lines; and real-time data analysis that enables better decision-making.

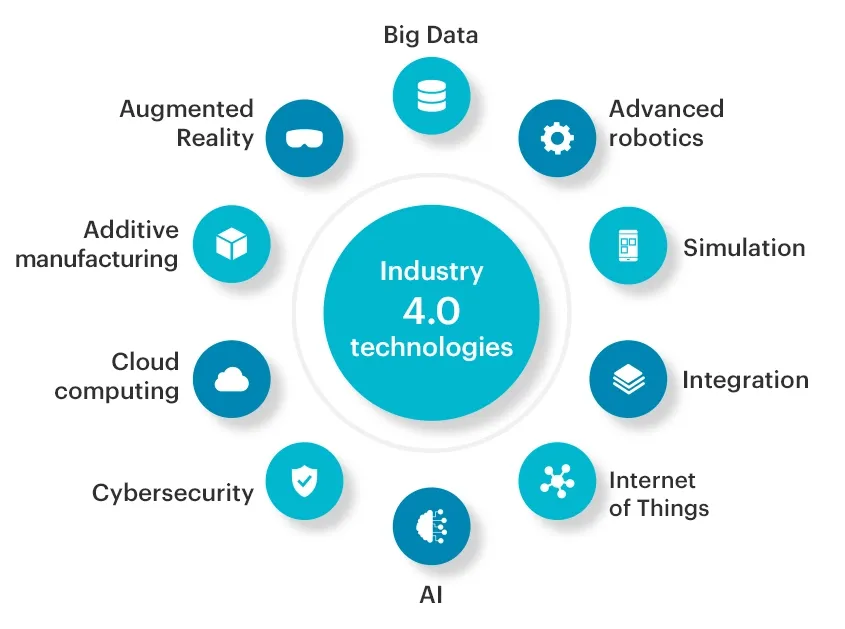

Industry 4.0 is revolutionizing how companies manufacture, improve and distribute their products. Manufacturers are integrating new technologies, including IoT, cloud computing and analytics, AI, and machine learning, into their production facilities and throughout their processes to collect and share data. Industry 4.0 concepts and technologies can be applied across all industrial companies, including discrete and process manufacturing and oil and gas mining segments. We are entering a fundamental shift in how products are produced that is deeply tied to IoT.

What Is Industry 4.0?

The automation of operations and technology integration into industrial systems are more prominent features of Industry 4.0. Artificial intelligence (AI), robots, the Internet of Things (IoT), 3D printing, augmented reality, and virtual reality are just a few of the combined technologies. This new paradigm will impact almost every area of our lives, including how we procure goods and services, how they are made, how we use our free time, and so on.

The manufacturing landscape is being fundamentally changed by Industry 4.0, leading to increased productivity and sustainability. From fashion brands that can speed up production cycles to automobile companies that employ AI-driven predictive analytics for proactive maintenance, businesses across all sectors embrace technology to gain a competitive edge in the market. Industry 4.0 will eventually enable organizations to boost product speed and accuracy while collecting crucial insights into client preferences. In addition, processes will become more automated and networked.

Industry 4.0 Elements

-

Smart factories: Factories that use interconnected devices, sensors, and advanced analytics to optimize operations and improve productivity.

-

Digital twin: A virtual replica of a physical system or process, used to simulate and optimize its performance.

-

Predictive maintenance: The use of data analysis and machine learning to predict when equipment is likely to fail, enabling proactive maintenance.

-

Augmented and virtual reality: Technologies used to enhance or simulate the physical world for industrial purposes, such as training and product design.

-

Cybersecurity: Ensuring the safety and defense of business networks and systems against online attacks.

By applying cutting-edge technology, Industry 4.0 seeks to improve industrial processes that are flexible, effective, and sustainable.

How Is Industrial Automation Changing the Landscape of Manufacturing?

Industrial automation is having a significant impact by enhancing productivity, precision, and safety in the manufacturing sector. Automation can be used to improve already-existing processes, including production and assembly lines, or to design brand-new ones. By removing needless human labor and improving task speed and efficiency, automation can help save operational costs and conserve resources. Moreover, automation enables producers to reprogram equipment to adapt to shifting market demands, increasing production flexibility swiftly.

The fourth industrial revolution, or "Industry 4.0," is being ushered in primarily because of industrial automation. To connect intelligent machines and other physical components, such as sensors and actuators, throughout the entire manufacturing process, manufacturers might use automation. As a result, these interconnected devices may automatically exchange information with one another, enabling manufacturers to immediately discover potential issues and potential fixes inside the manufacturing cycle. As a result, production procedures become quicker, more dependable, and safer for employees. In addition, manufacturers can produce highly complex things more accurately than ever, thanks to improved automation and advanced machine learning capabilities.

What Are the Advantages of a Connected Factory?

Businesses must first assess their technologies and processes to participate in Industry 4.0. They should also look for platforms with the most recent automation systems. Furthermore, managers must be aware of the ramifications of implementing Industry 4.0 to decide how to integrate new technology into their operations. Finally, businesses should also consider spending money on staff training, which is essential for educating staff members on the latest systems and enabling them to perform more productively and efficiently.

Businesses should consider partnering with technology suppliers to access the most recent Industry 4.0 technologies. As a result, they will be able to grasp better how to take advantage of recent technological advancements and established patterns, keeping them one step ahead of the competition. Businesses should also pay close attention to data security and ensure that precautions are taken to guard against abuse or illegal access. Furthermore, companies must stay current on Industry 4.0's most recent advancements and be aware of future changes that may impact their business operations.

What Are the Challenges and Risks with Automation and Signal Processing?

Automation and signal processing bring a set of risks and challenges that must be addressed. These include potential changes to existing artificial intelligence applications, cyber security risks related to process control networks, and privacy issues related to data collection and storage. Additionally, there are legal concerns related to the development of autonomous robots or devices that could operate independently of human control. Companies must ensure they have the necessary safeguards in place to protect against these risks and minimize their exposure to liability.

Choosing the best solutions for automation and signal processing can be a complex and overwhelming task. Companies must evaluate the existing or potential risk of failure, consider the different available technologies for implementation, and assess the scalability required to accommodate future expansion or increased demand. Furthermore, organizations should identify any conflicts between legacy systems that are being replaced such as by data format incompatibility or shortened response times due to increased processing speeds caused by automation. Security is also an issue that needs careful attention, as automated processes typically require high levels of access rights when creating or modifying structured data from across multiple systems. It is essential that appropriate security controls are put in place to prevent unauthorized access to vulnerable assets.

We can help

Few examples in Industry 4.0, are:

- IoT Solutions: Provide solutions for integrating the Internet of Things (IoT) into industrial processes, enabling the gathering and analyzing of data from linked devices and sensors.

- Cybersecurity Solutions: Provide cybersecurity solutions to shield industrial systems and data from online threats and attacks.

- Big Data Analytics Solutions: Offer big data analytics solutions to handle and analyze the enormous amounts of data produced by industrial operations, enabling in-the-moment decision-making and preventative maintenance.

- Cloud Computing Solutions: Offer cloud computing solutions to store, process, and analyze industrial data, allowing for remote access and communication between team members and stakeholders.

- Robotic process automation solutions: Provide robotic process automation solutions to automate repetitive operations and free up human workers for more complicated and value-added activities.

- Augmented Reality (AR)/Virtual Reality (VR) Solutions: Provides enhanced training, visualization, and collaboration in industrial settings.

- Supply Chain Management Solutions: Provides optimized flow of goods and information throughout the supply chain, reducing costs and increasing efficiency.

These are just a few ideas. Please connect with us to have a solution tailored specifically for you in support of Industry 4.0, which enables the development of smart, connected factories to quickly adapt to shifting market conditions and produce high-quality goods at scale.